04 Apr Circular Economy in Packaging: Addressing Plastics in Reverse Value Chains for Sustainability

Plastic pollution has emerged as a critical environmental challenge, with the packaging industry being a significant contributor to the growing crisis. Around 40% of global plastic waste comes from packaging, harming marine life through ingestion and entanglement, disrupting ecosystems, and introducing microplastics into the food chain. With 141 million tons of plastic packaging produced each year—and nearly one-third leaking into the environment—the need to tackle plastic pollution is more urgent than ever.

Shifting from a ‘take, make, dispose’ linear economy to a circular model, where materials are continuously reused, is essential to address this crisis. Reverse value chains, which focus on reclaiming materials after consumer use and reintegrating them into the production cycle, offer a viable pathway toward sustainable packaging solutions.

Understanding Reverse Value Chains in Packaging

Reverse value chains play a key role in circular economies by bringing used materials back into the supply chain for reuse or recycling. They help collect, sort, and reintegrate used packaging materials into production, reducing waste and the need for new plastics. This process not only keeps materials in use but also improves resource efficiency and lowers the environmental impact of packaging. The main steps involved include:

- Collection and Return Systems: Establishing take-back programs and drop-off points to recover used packaging.

- Sorting and Processing: Ensuring that collected materials are sorted effectively to maintain high-quality inputs for reuse and recycling.

- Reintegration into Supply Chains: Reintroducing recycled materials into production, reducing demand for virgin raw materials.

Several countries and companies are setting benchmarks in circular packaging, offering models for industry-wide adoption, particularly in managing reverse value chains:

Germany’s Pfand system

Germany operates a bottle return system known as Pfand, where consumers pay a deposit when purchasing certain beverages. This deposit is refunded upon returning the empty container, which is then either recycled or reused. Businesses that sell Pfand containers are required to accept returns and facilitate the deposit refund. The system covers reusable glass and PET (polyethylene terephthalate) bottles, refillable up to 50 and 25 times respectively, and single-use containers that are recycled. Environmental advocates are now calling for the system’s expansion to include glass jars and cartons, highlighting the potential for greater circularity in packaging.

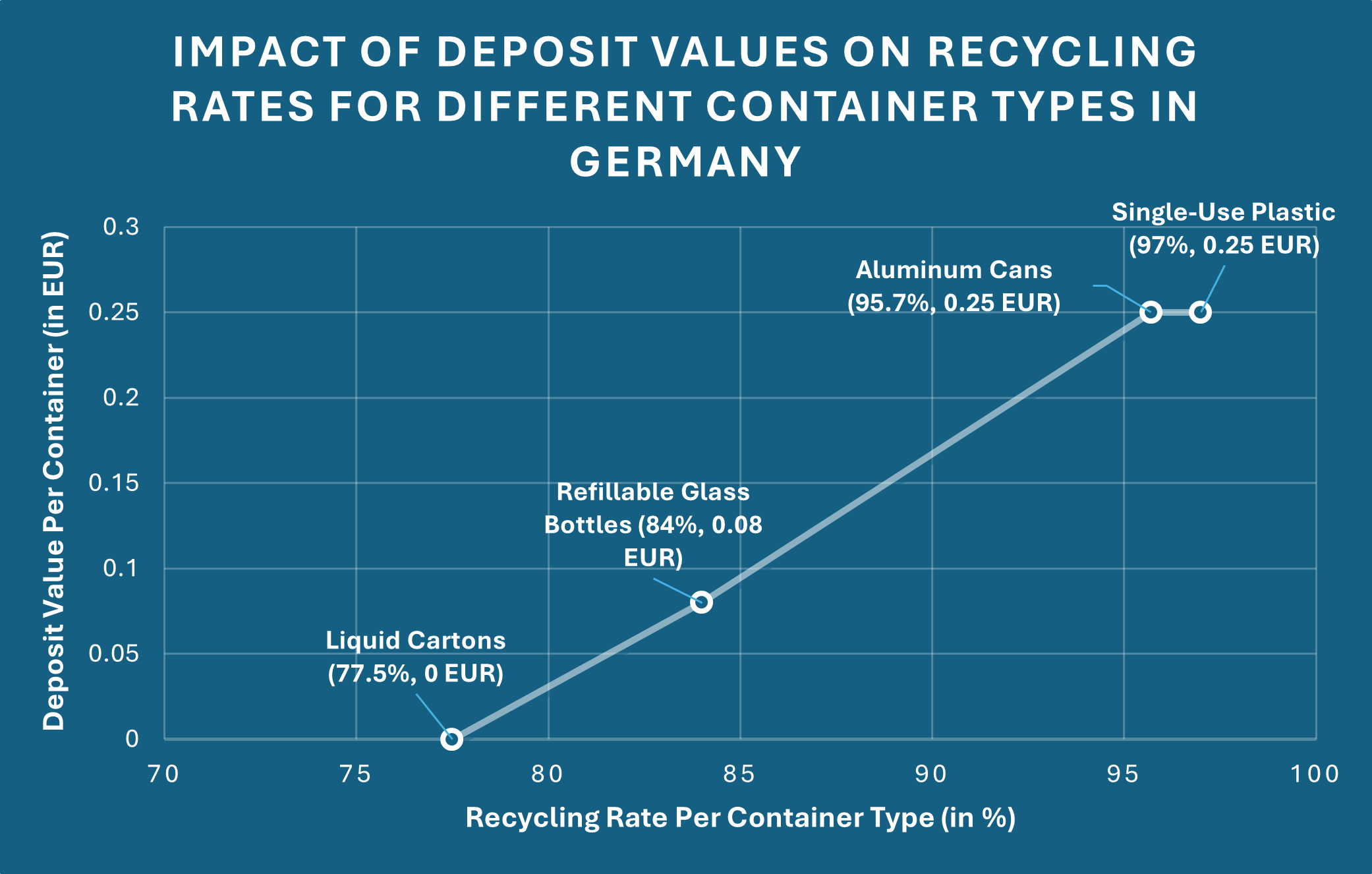

Key:

- Deposit value: The refundable amount charged on a container (e.g., bottle or can) at purchase, returned to the consumer upon recycling.

- Recycle rate: The percentage of containers collected and processed for recycling.

The graph illustrates a clear correlation between deposit values and recycling rates for different container types in Germany. This trend highlights that higher deposit values act as a stronger incentive, driving higher return rates and encouraging greater consumer participation in recycling efforts.

The Body Shop’s Return, Recycle, Repeat Program

The Body Shop’s Return, Recycle, Repeat (RRR) program, launched in 2021, tackles hard-to-recycle beauty and cosmetics packaging that traditional systems cannot process. Customers can return used packaging at 226 drop-off points nationwide, diverting waste from landfills and incineration. To boost participation, The Body Shop offers in-store credit for returning five own-brand packaging items in a single transaction. Since inception, the program has collected over 8.4 tonnes of waste and recycled more than 65,000 items, exemplifying a circular economy model that combines consumer engagement with effective recycling systems.

Amazon’s Sustainable Packaging Initiatives

Amazon’s packaging innovations in the UK exemplify a best practice in minimizing environmental impact. Since 2015, the company has reduced outbound packaging weight by over 38%, eliminating more than 1.5 million tons of material. All paper bags, cardboard envelopes, and boxes used in the UK are 100% recyclable, and since 2022, Amazon has stopped using single-use plastic delivery bags for orders from its own distribution network across the UK and Europe. By leveraging lab testing, machine learning, and materials science, Amazon optimizes packaging to fit more orders per delivery, contributing to its goal of achieving net-zero carbon by 2040.

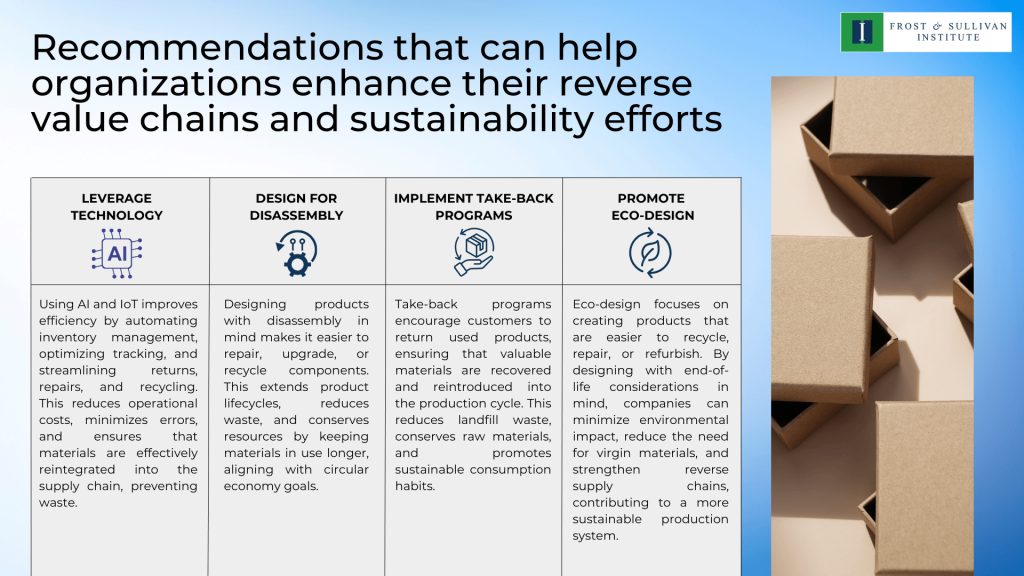

These best practices highlight effective strategies for advancing circularity in packaging. To further accelerate progress, the following recommendations can help organizations enhance their reverse value chains and sustainability efforts.

Strengthening reverse value chains goes beyond reducing waste—it is about redefining the role of packaging in building a sustainable future. Companies must prioritize innovation in recycling, reuse, and material recovery while integrating technology and collaboration to optimize resource efficiency. By proactively enhancing these systems, businesses can minimize waste, reduce reliance on virgin materials, and create a more sustainable future. Now is the time to act—adopting circular strategies is not just an environmental responsibility but a competitive advantage in a rapidly evolving market.

Blog by Sakthi Kumararaja,

Associate, Frost & Sullivan Institute